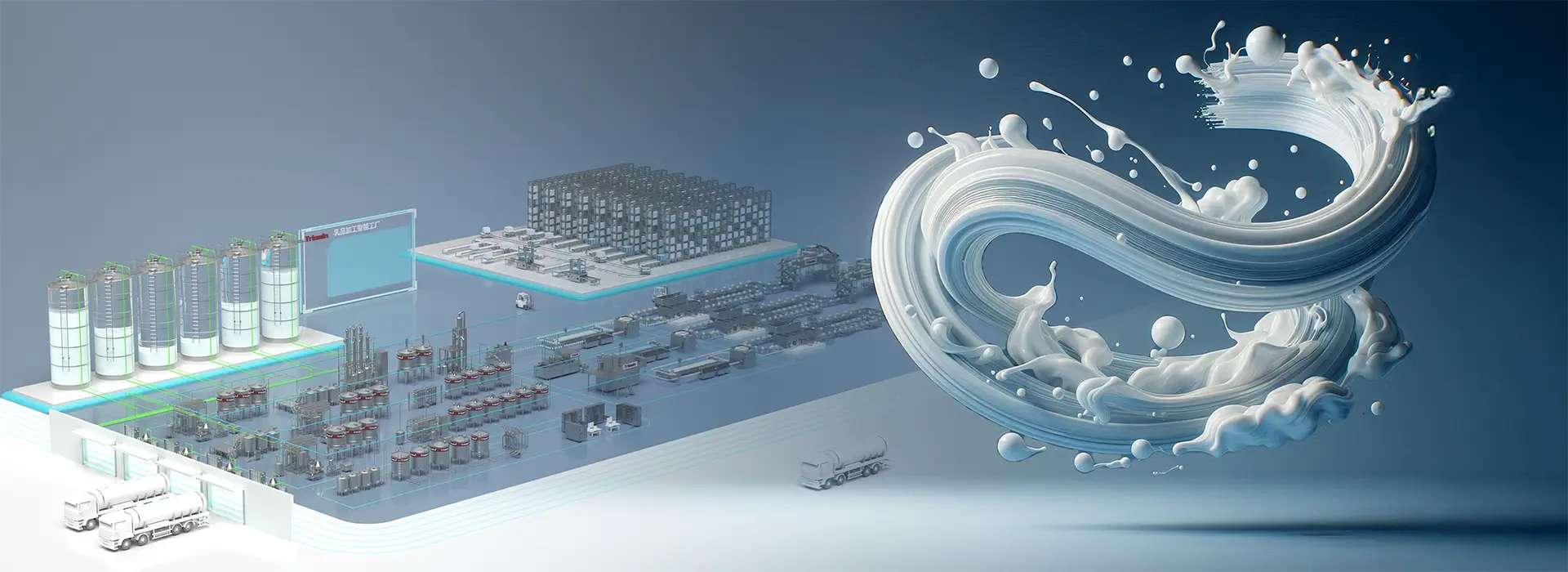

Triowin can offer components, equipment and process lines for all types of milk powder such as whole milk powder, skim milk powder, whey powder, etc.

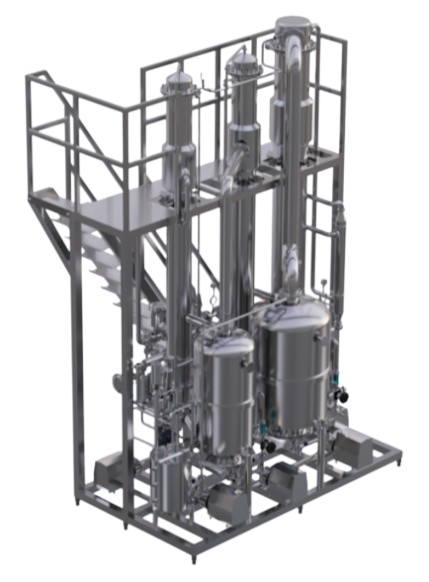

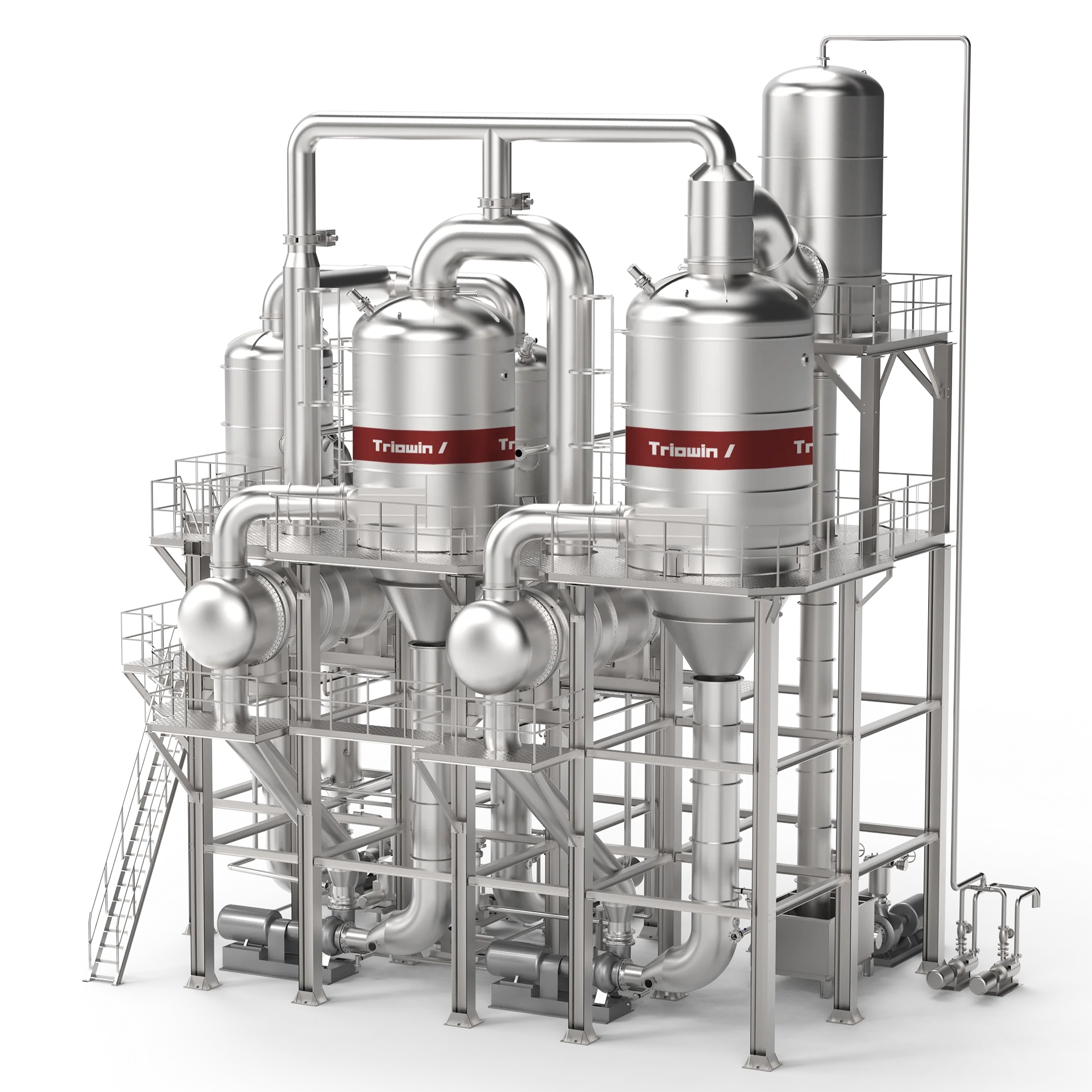

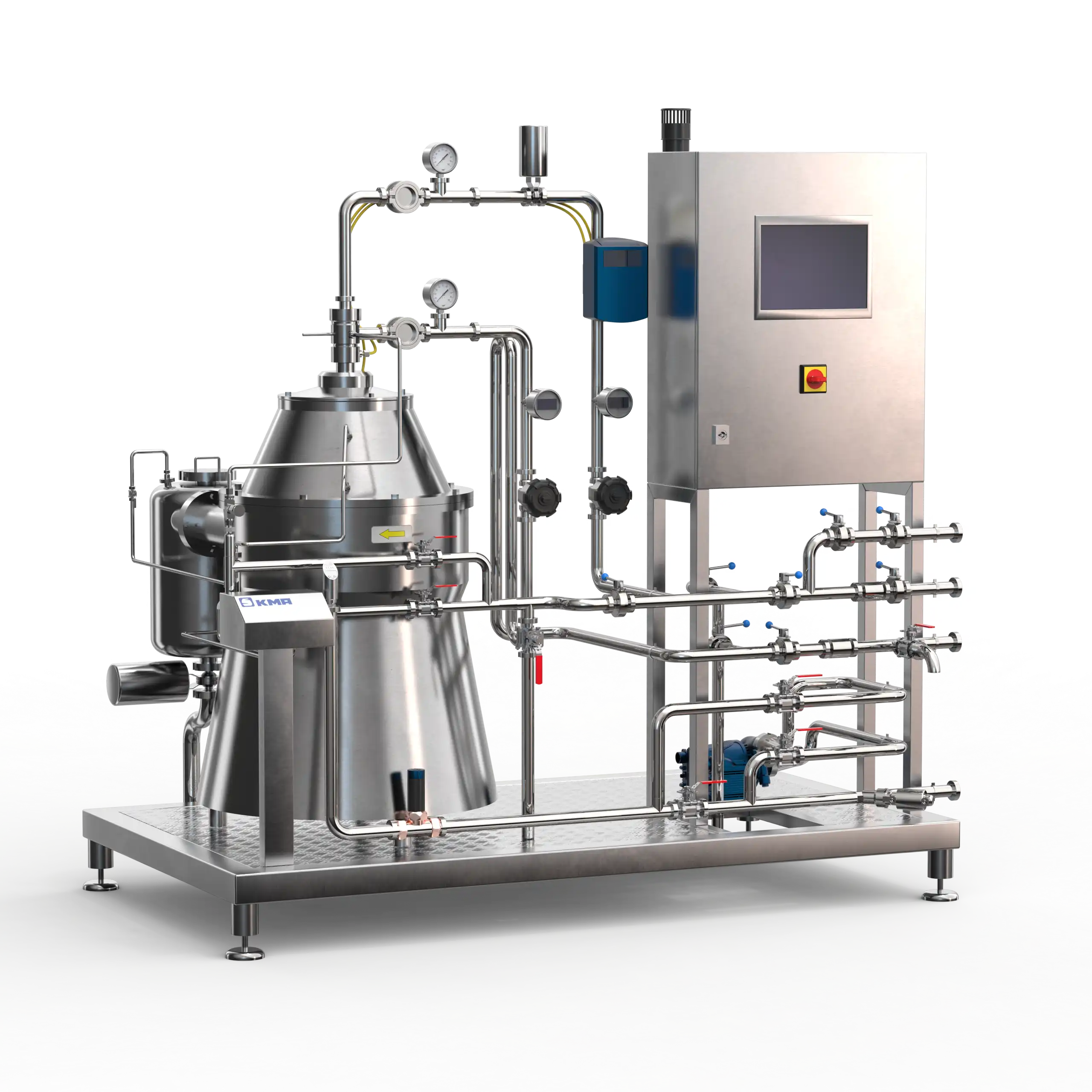

We continuously innovate to develop new solutions that could help you save energy, recycle waste heat and water and improve your environmental footprint. Whatever your production scale, our equipment is designed to help you precisely control and optimize just about every stage from milk reception, ingredient mixing, pasteurization and standardization, through to milk concentration and spray dryer, final product packaging.

As a producer you want to be confident that your processes are closely monitored and controlled, at every stage, to help maximize yield, reduce waste and support sustainability.

And of course, our equipment and process solutions are designed to help ensure that from process start to end your products retain their key nutritional values and functional properties, working with Triowin you can be confident that your plant will help you to achieve maximum productivity from key ingredients without bottlenecks and delays.

Download Materials

Download Materials

'

'