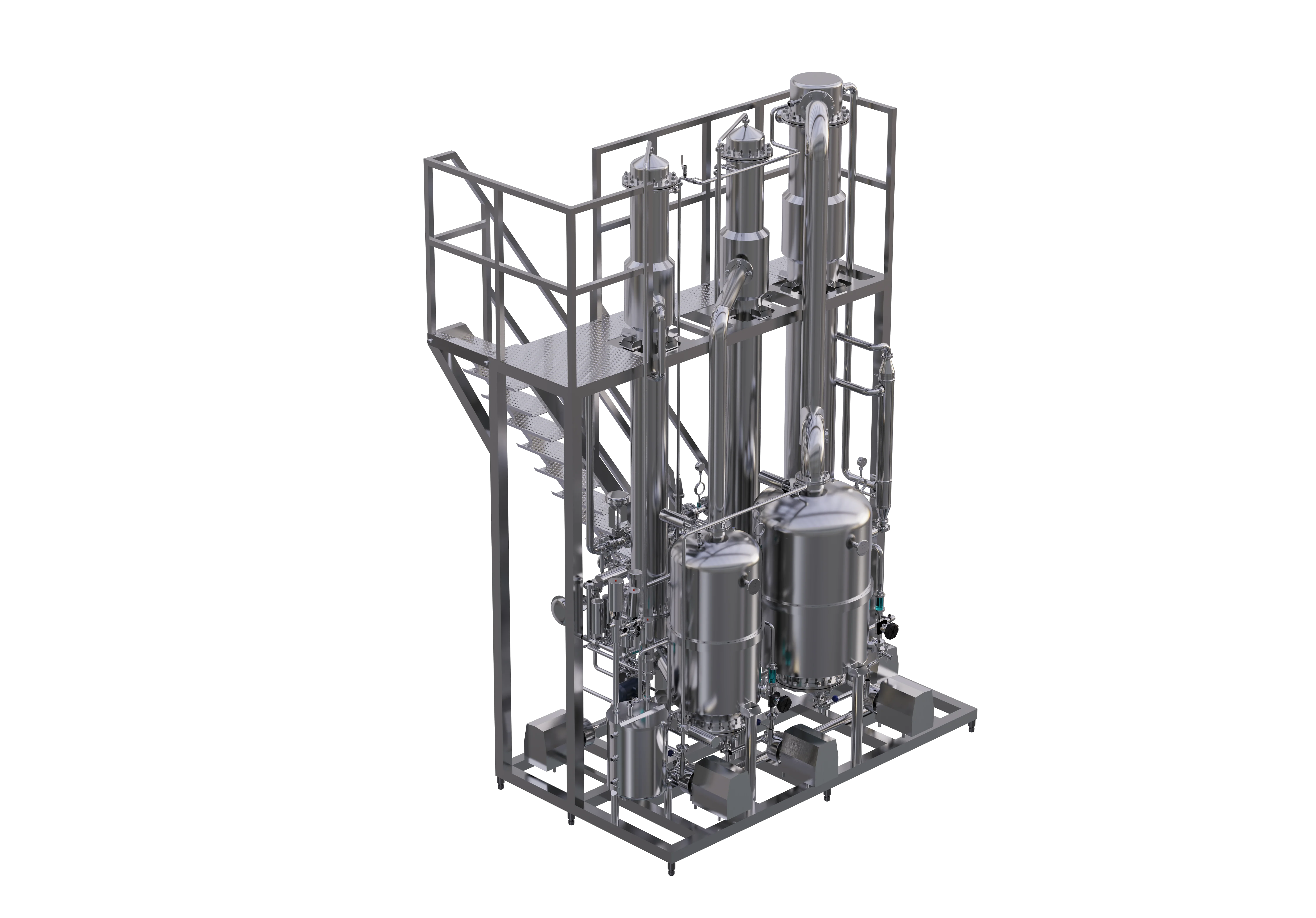

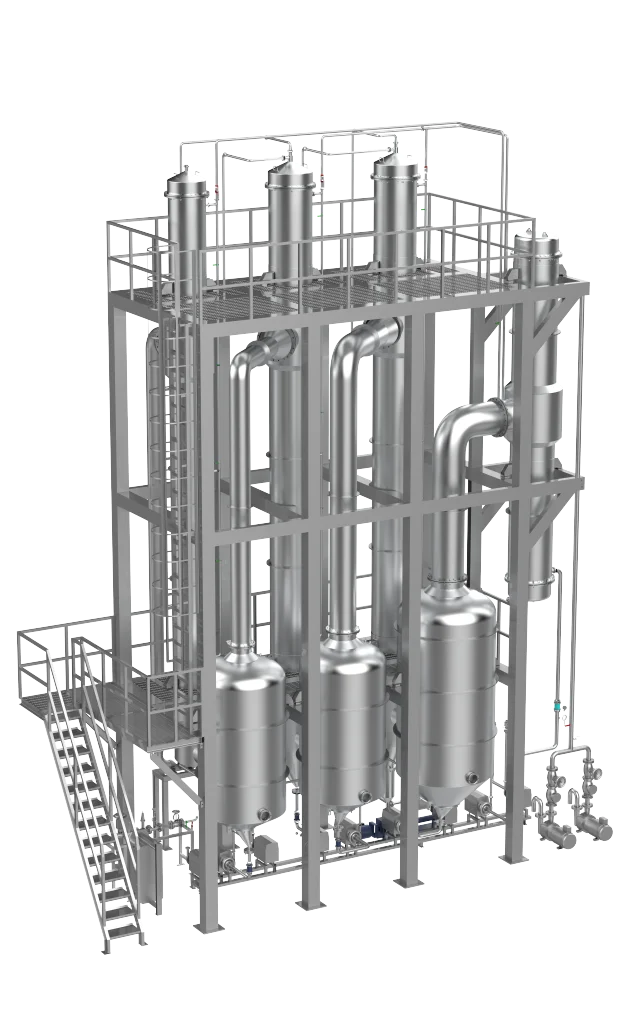

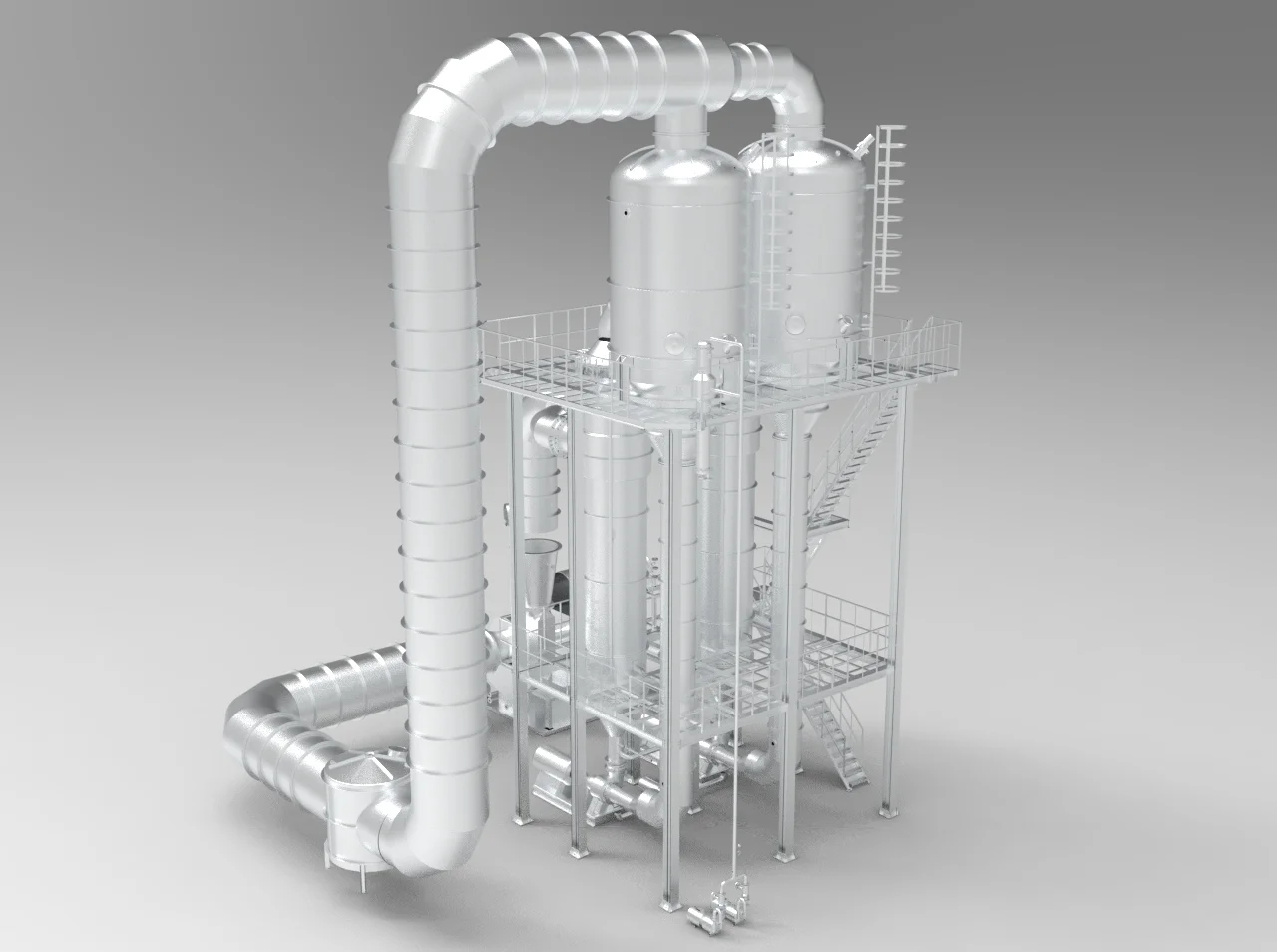

Energy conservation and water saving

The MVR evaporator saves over 80% of energy, over 90% of condensate water and reduces the floor space by over 50% compared with traditional evaporators.

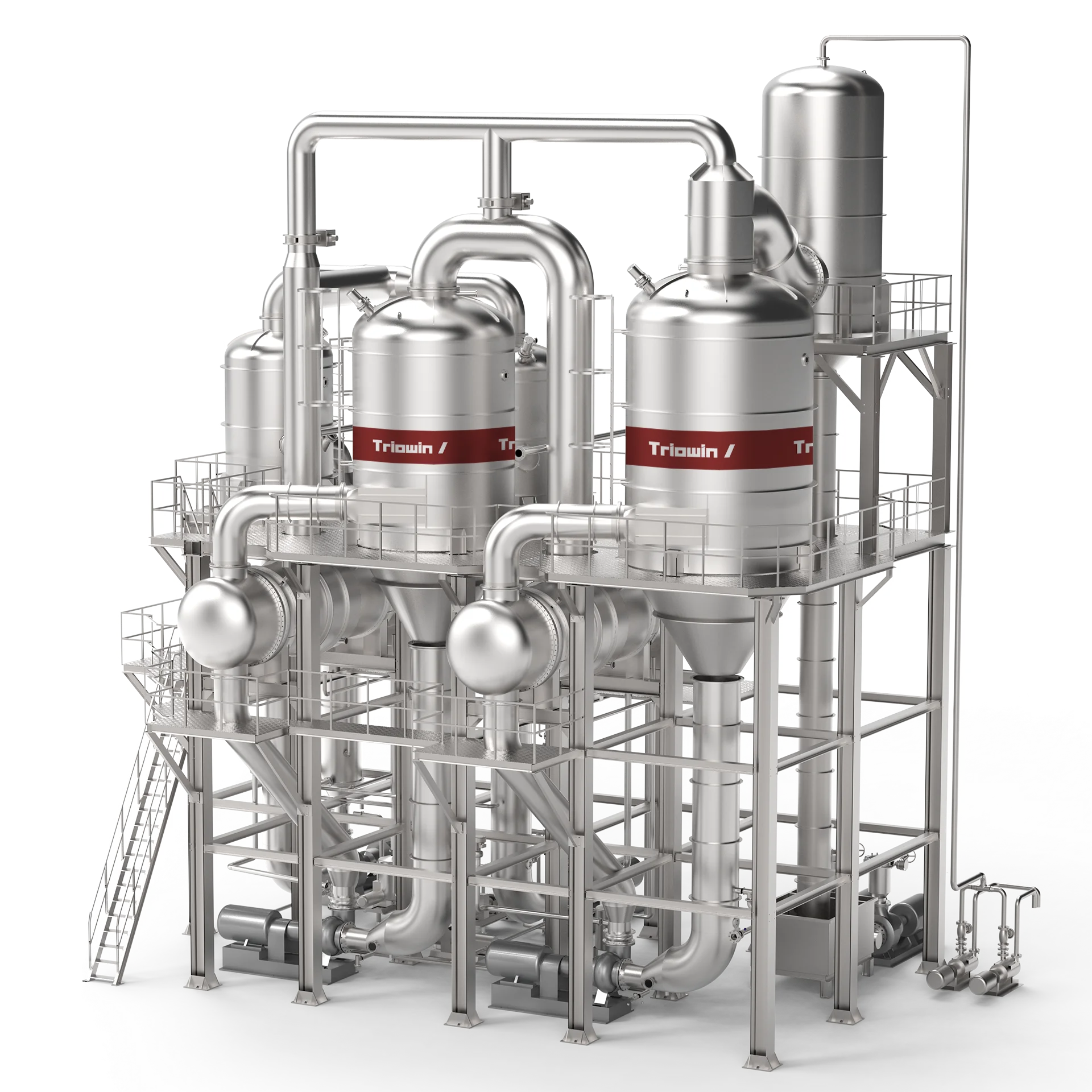

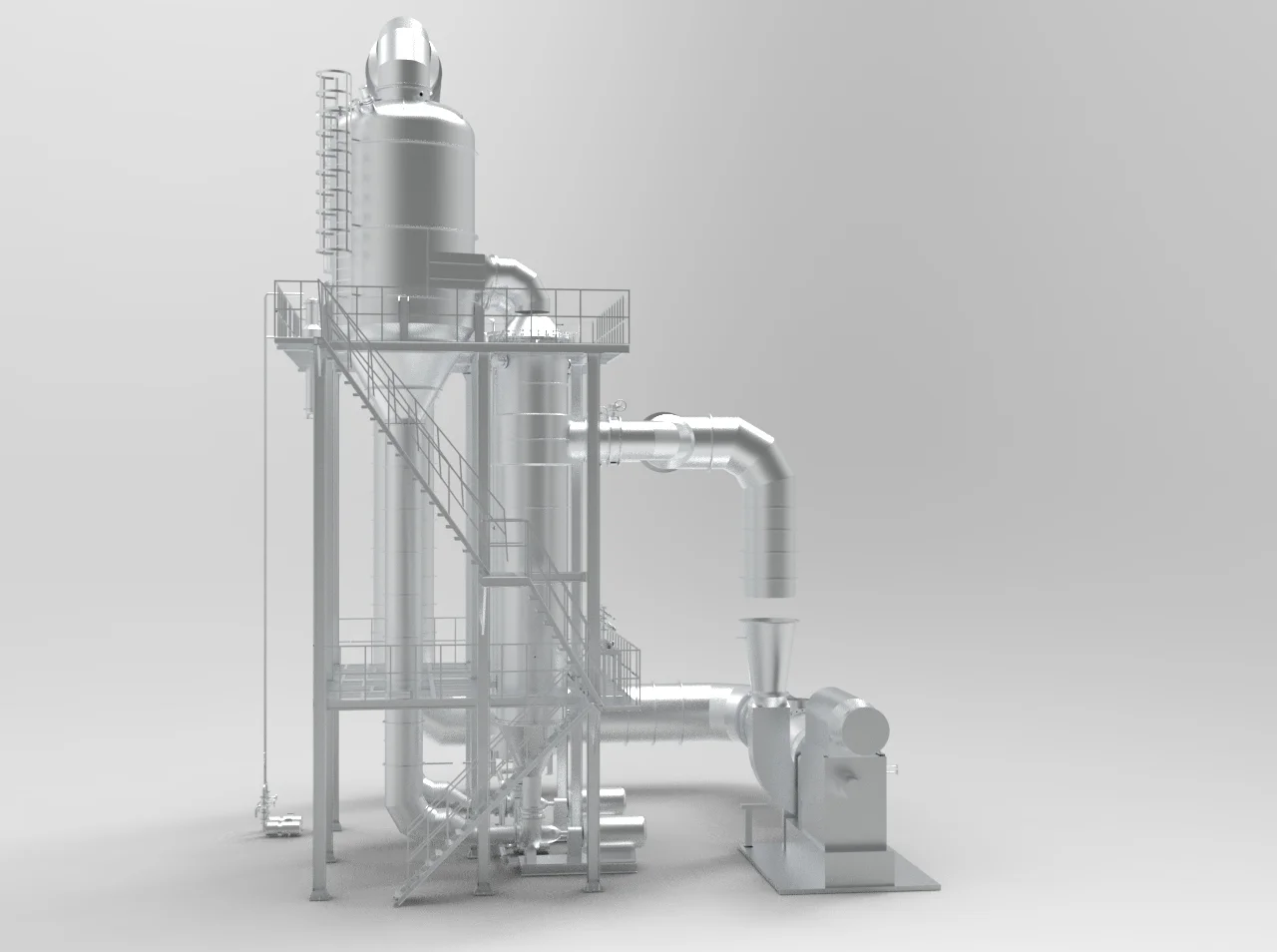

High steam utilization rate

The secondary steam is fully utilized. The economic efficiency of the raw steam is equivalent to that of a 30-effect multi-effect evaporation, reducing the demand for external heating and cooling resources, lowering energy consumption and reducing pollution.

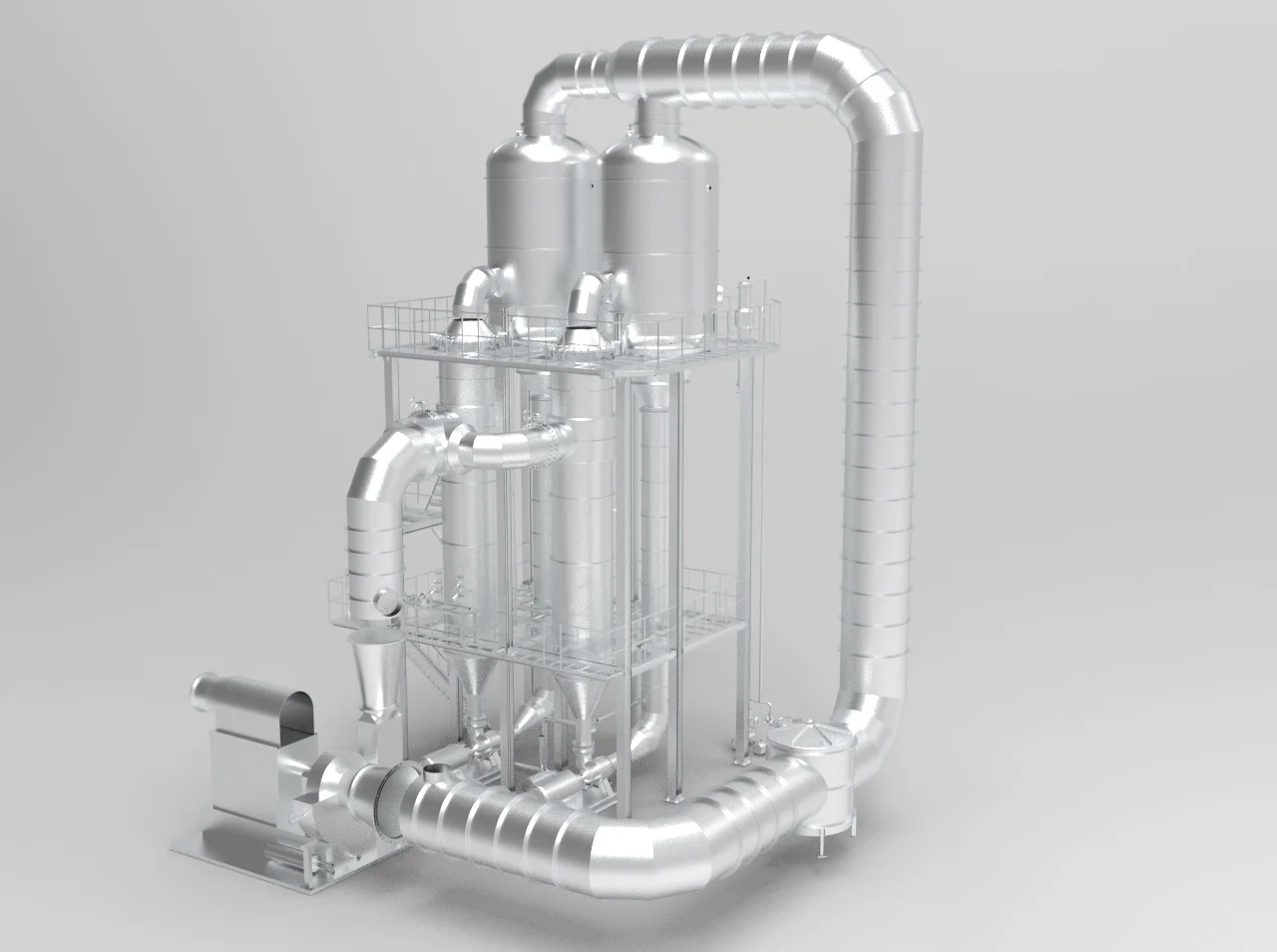

Mild evaporation

Due to the use of a compressor as the heat source, the temperature difference is much smaller compared to traditional evaporators, enabling gentle evaporation, which greatly improves product quality and reduces scaling.

Simple and reliable

It does not require a condenser or only needs a very small area condenser. The structure and process are very simple. It is fully automatic operation, can run continuously, and is safe and reliable.

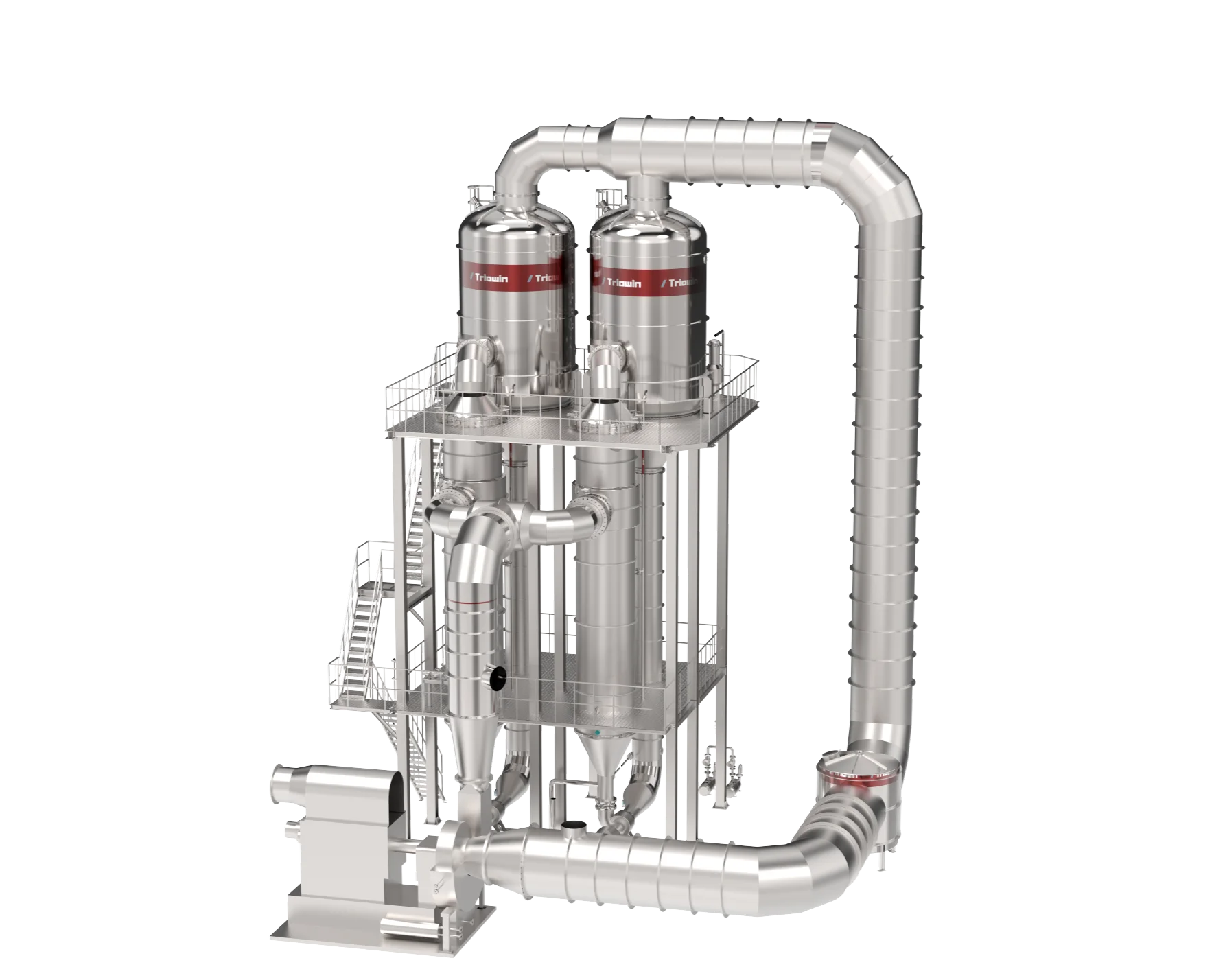

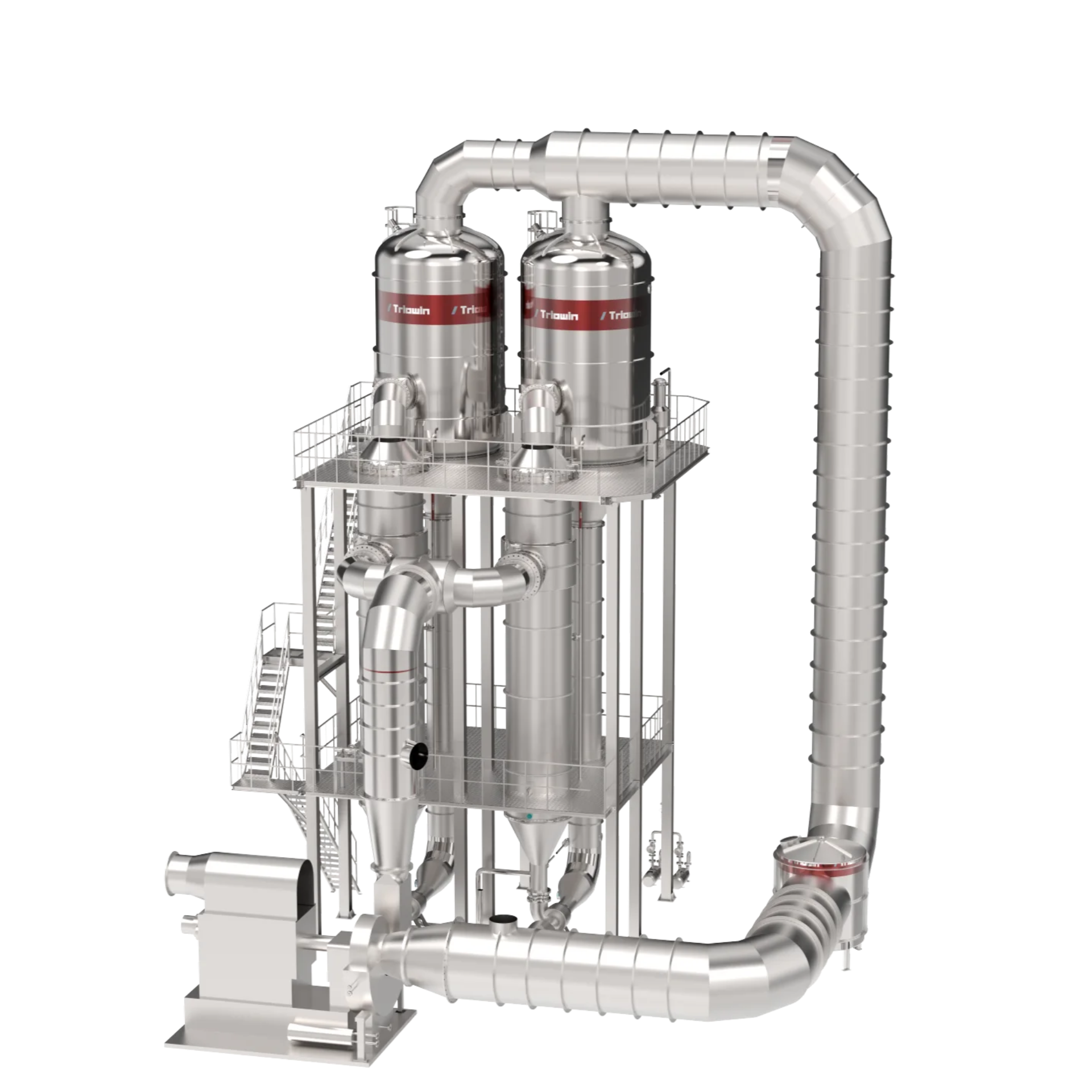

Small heating denaturation

This evaporator enables the evaporation of materials at low temperatures (evaporation temperature 40℃-100℃), ensuring uniform liquid distribution, no material loss, low risk of coking, and minimal material denaturation during heating.

Scraper heater structure

The scraper heater structure features a high heat transfer coefficient value, large evaporation capacity, and an evaporation intensity that can reach 200kg/m ² ·hr, with high thermal efficiency.

The heating time of the materials is short

The heating time for the material is short, approximately 5 to 10 seconds. It operates under vacuum conditions, which is more beneficial for heat-sensitive materials, ensuring that no decomposition occurs among various components and guaranteeing product quality.

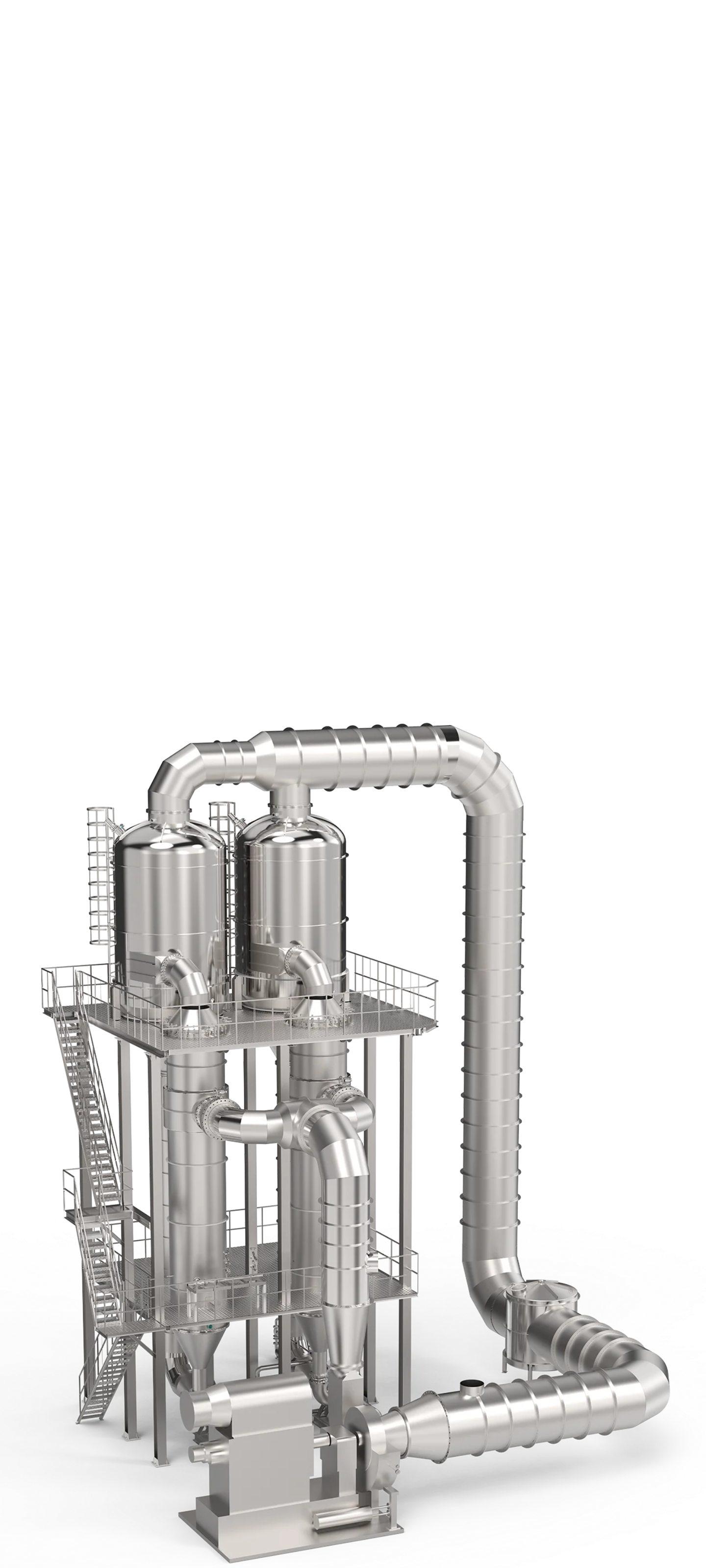

It has a wide range of adaptability to viscosity changes

It has a wide range of adaptability to viscosity changes and can handle both high and low viscosity materials. The material viscosity can reach up to 100,000 centipoise (CP).

The vacuum resistance drop is small

Due to its unique evaporation form, the processed material only forms a film on the evaporation surface and does not accumulate there. Therefore, there is no problem of the static pressure of the liquid column counteracting the vacuum degree as in other evaporation forms (in other evaporation forms, the vacuum degree only reflects the vacuum degree of the main surface of the liquid phase in the system). The vacuum degree displayed by the system is the vacuum degree of the material evaporation.

High evaporation intensity

The improvement of vacuum degree reduces the boiling point of the processed material, increases the temperature difference driving force of the cold and hot media, and the forced action of the scraper makes the liquid film turbulent and thinner. The self-cleaning effect of the scraper inhibits the formation of the scale layer on the heating surface, increases the heat transfer coefficient, and enhances the evaporation intensity.

The heating time is short

As the scraper evaporator is a special type of falling film evaporator, the residence time of the material on the heating surface is very short, approximately 10 to 60 seconds (varying depending on the specification), making it particularly suitable for processing heat-sensitive materials.

Great operational flexibility

The amount of material entering the evaporator per unit time determines the thickness of the liquid film formed on the heating surface. As the liquid film of the scraper evaporator is forcibly formed by the scraper, the feed rate can be adjusted within a wide range.