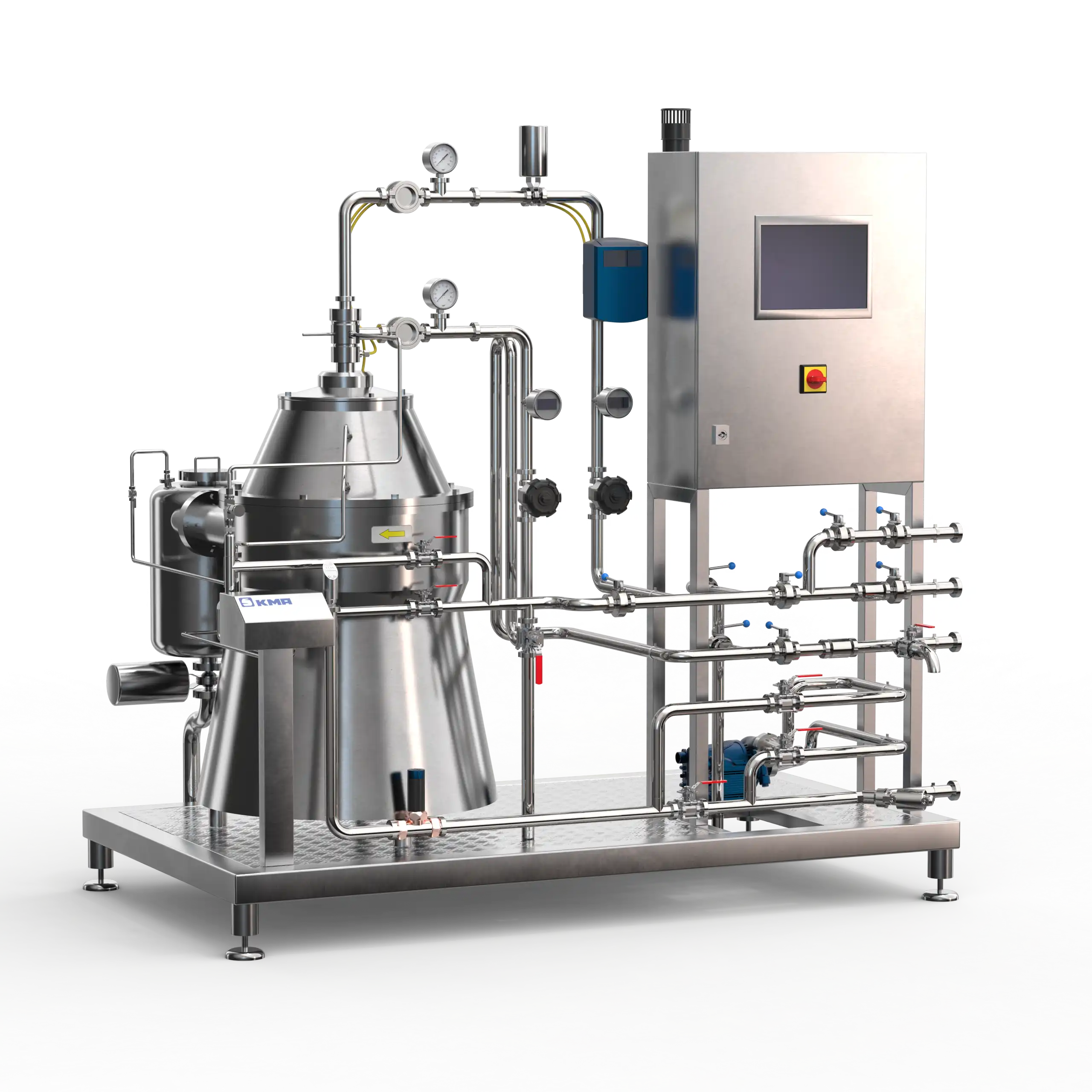

With milk skimming separators, raw milk can be separated continuously into two liquid phases, i.e. skimmed milk (heavy phase) and cream (light phase). At the same time, the solids contained in the raw milk (milk sludge) are separated.

Solutions

- Solutions

-

Industry Solutions

- Project Cases

-

Industry SolutionsDelivering One-stop Solutions for Intelligent Production

-

Project CasesLeveraging Intelligence for Sustainable Productivity in Future Factories