Triowin is the leader supplier of filling machine and Intelligent packing solution

Filling equipment including fillers for aseptic liquid dairy, juice; Cup filler for yogurt etc.

Packing euipment including , traypacker, shrinker, palletizer ect.

Triowin is the leader supplier of filling machine and Intelligent packing solution

Filling equipment including fillers for aseptic liquid dairy, juice; Cup filler for yogurt etc.

Packing euipment including , traypacker, shrinker, palletizer ect.

A brick-shaped aseptic carton filling machine is designed to fill sterile liquid products (like milk, juice, soup, and wine) into pre-sterilized, multi-layer paperboard packages in a continuous, automated process. "aseptic," meaning the product and the package are sterilized separately and then brought together in a sterile environment, allowing the product to be stored for 6-12 months without refrigeration

The entire machine operates on a simple but critical principle: sterilize the product, sterilize the packaging material, and fill and seal in a sterile environment.

| Productivity | 7500BPH for 125-350ml | 6000BPH for 1000ml |

| Package shape | Brick base shaped, brick slim shaped | |

| Packaging material | PE/PAPER/PE/AL/PE/PE aseptic packaging material roll | |

| Electric power | 30kw(mechanical transmission:5kw)electric heating power:25kw) | 34kw (mechanical transmission:4kw, electric heating power:30kw) |

| Rated voltage | 220 V/380V | |

| Power frequency | 50Hz/60Hz | |

| Compressed air | 0.4-0.6Mpa 1. 0m³/min | |

| Technological process | Form feed – print date – sterilize – filling - shaping | |

| Operation mode | PLC control, man-machine interface operation | |

| Shelf life | In 25-30℃,juice 12 months, milk 6 months | |

| Outside measurement | L×W×H=4500×1600×4000mm | |

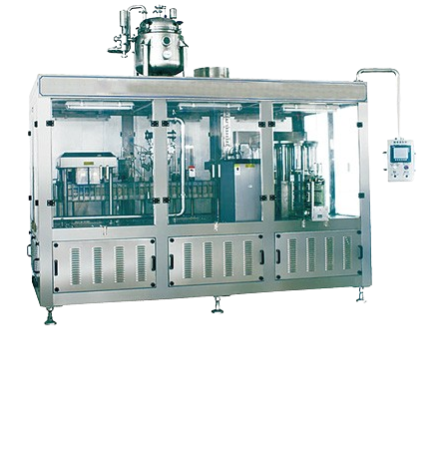

This machine is specially designed for molding, filling and sealing gable paper box with single line and single body gear box control. It is applicable to filling various liquid foods (such as milk, yoghurt, fresh oil and fruit juice drinks).Combined with its options, it can fill high-viscosity, granular or solid food products or other products. New CAP-PAC capping machine can be fixed on this packing machine directly to weld various plastic caps onto the preserved opening on the gable box directly ultrasonic technique.

Advantages:

| Model | WDB-1000 | WDB-2000 | WDB-3000 |

| Production capacity | 1000box/h for250,500ml 500ox/h for 1000ml |

2000box/h for250,500ml 1000ox/h for 1000ml |

3000box/h for250,500ml 1500ox/h for 1000ml |

| Air consumption | 85psi/7bar,2.5scfm/65lpm | 85psi/7bar,4.0scfm/113lpm | 85psi/7bar,6.5scfm/184lpm |

| Cooling water | ℃ | 50f/10℃,2.0gpm/7.6 | 50f/10℃,2.0gpm/7.6 |

| Power consumption | 22kw | 26kw | 30kw |

| Control method | Semi–auto electric control | Semi–auto PLC control | Fully–auto PLC control |

| Size | 3500*1500*2800mm | 3500*1500*2800mm | 3500×1500×2800mm |

| Weight | 2440kg | 2450kg | 2460kg |

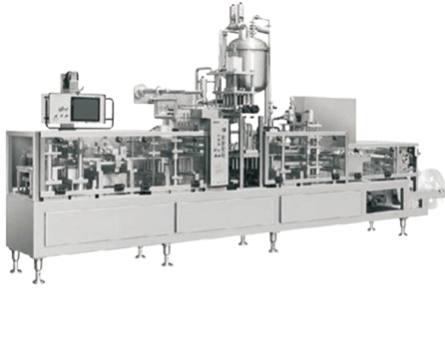

This machine is suitable for milk, soy milk, peanut milk, fruit juice, and other products of aseptic packaging. Automatic completion of bag making, filling, sealing, printing date, counting, bag for cleaning, etc. Man –machine interface, programmable control, pneumatic, the servo electrical engineering drive, advanced sterilization and aseptic security. The man-machine interface, PLC, photoelectric, pneumatic, lubrication, aseptic processing, servo system and all kinds of valve body adopt international famous brand. And the material of SUS 304, 316 are used for sanitary warranty.

| Model | WJB-2500,6000 |

| Film width | 240mm,320mm |

| Production capacity | 2500,6000pouch/hr |

| Filling volume | 200-500ml |

| Power | 380V/50Hz,220V/60Hz |

| Power consumption | 10kw |

| Air compressing | 0.6Mpa |

| Vapor steam | 0.4Mpa |

| Hydrogen consumption | 100 pouch/0.5L |

| Size | 1000×1000×2600mm |

Full close liquid packing machine: applicable to automatic bag style package of liquid foods. Such as milk, bean milk, peanut milk, fruit milk, juice, beverage, soy sauce and acetic acid, tec. This machine is probably sack, filling, sealing, counting, date printing and UV sterilizing are automatically accomplished in a one-off.

| Model | YTB-2500,5000 |

| Film width | 240mm,320mm |

| Production capacity | 2500,5000 pouch/hr |

| Packing volume | 100-500ml |

| Filling precision | ±2% |

| Power | 380V/50Hz,220V/60Hz |

| Size | 1250*820*2500mm |

| Filling mode | Filling by spontancously flowaing from the hight position kettle |

The TWD series machines are applicable to the packaging production of yogurt, milk, beverage, seasoning, etc. With the function of accomplishing paper cup or plastic cup loading, cup lacating, filling, lid placing, sealing, date printing, covering and product transportation full-automatically. These machines are equipped with world famous top brands system. This series machines, which have the optional systems of 100-class laminar flow protection, fruit particle and essence dynamic mixture, high-temperature filling and mobile code printing etc. And is the first choice for high-efficiency, energy saving and full-automatic production.

| Model | TWD-600F | TWD-300F | TWD-200F | TWD-100F |

| Production capacity | 20000c/h(150ml) | 10000c/h(150ml) | 6600c/h(150ml) | 3000c/h(150ml) |

| Operation mode | Linear step | Rotary step | ||

| Preformed cup type | Plastic cup, paper cup | |||

| Lid type | Precut lid, rolling film | |||

| Total power | 18kw | 9kw | 7kw | 4.5kw |

| Operating power | 10kw | 5kw | 4kw | 2.2kw |

| Working air pressure | 0.7Mpa | 0.7Mpa | 0.7Mpa | 0.7Mpa |

| Air consumption | 1.5m³/min | 1.1m³/min | 0.9m³/min | 0.5m³/min |

| Overall dimension | 9300×3750×4000mm | 4200×3000×2880mm | 4200×2900×2880mm | 2900×2100×2750mm |

| Weight approx | 6t | 3.2t | 2.6t | 1.8t |

Fulling and Aluminum Foil Sealing Machine

This machine is used for production of bottle of milk, locate milk, soy milk, juice etc. The machine completes the process of vacuum negative pressure filling, cap forming, capping (optional) and electricity heat sealing automatically. Adopting world famous brand products from Germany, America, japan, etc. Including various sorts of valve and the system of PLC, optic-electronic and temperature control, pneumatic control and automatic lubrication, etc. It is the best choice for middle size enterprises.

| Model | Capacity(BPH) | Bottle size | Power(kw) | Measurement(m) |

| 10/10 | 4000 | Bottle diameter:∮50-90 Bottle height:110-280 |

3 | 1.6×1.4×2.1 |

| 20/12 | 8000 | 3.2 | 1.8×1.6×2.1 | |

| 24/14 | 10000 | 3.2 | 1.9×1.65×2.1 | |

| 30/30 | 18000 | 4 | 2.4×2×2.1 |

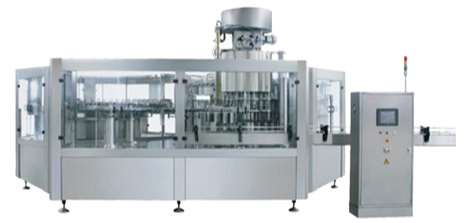

The series of machine are the integrated rinsing. Filling and capping machine, mainly suitable for producting the bottled mineral water, pure water, fruit juice, wine and so on. The output from 3000 to 36000 bottles per hour.

| Model | QGF14-12-5 | QGF18-18-6 | QGF18-18-6 | QGF18-18-6 | QGF18-18-6 |

|

Production capacity (600ml)(b/h) |

4000 | 8000 | 12000 | 15000 | 18000 |

| Filling precision | >±5mm liquid level | ||||

| Polyester bottle standard (mm) | Bottle diameter:∮50-∮100 Height:150-320 | ||||

| Suitable cap shape | Plastic screw cap | ||||

| Water pressure of washing bottle (Mpa) | 0.18 | ||||

|

Water consumption of washing bottle(kg/h) |

800 | 1600 | 2500 | 3500 | 4500 |

| Spraying position | 5 | 5 | 6 | 12 | 20 |

| Dripping position | 3 | 3.5 | 14 | ||

|

Air source pressure (Mpa) |

4 | ||||

|

Air consumption(m³/min) |

_ | 0.3 | 0.4 | 0.5 | 0.6 |

| Power (kw) | 4.23 | 5.03 | 6.57 | 8.07 | 5.6 |

| Weight(kg) | 2500 | 3000 | 4000 | 5000 | 6000 |

| Size(mm) | 2300×1550×250 |

2640×1800×2500 |

3000×2000×3150 | 3600×2800×3150 | 4500×3400×3150 |