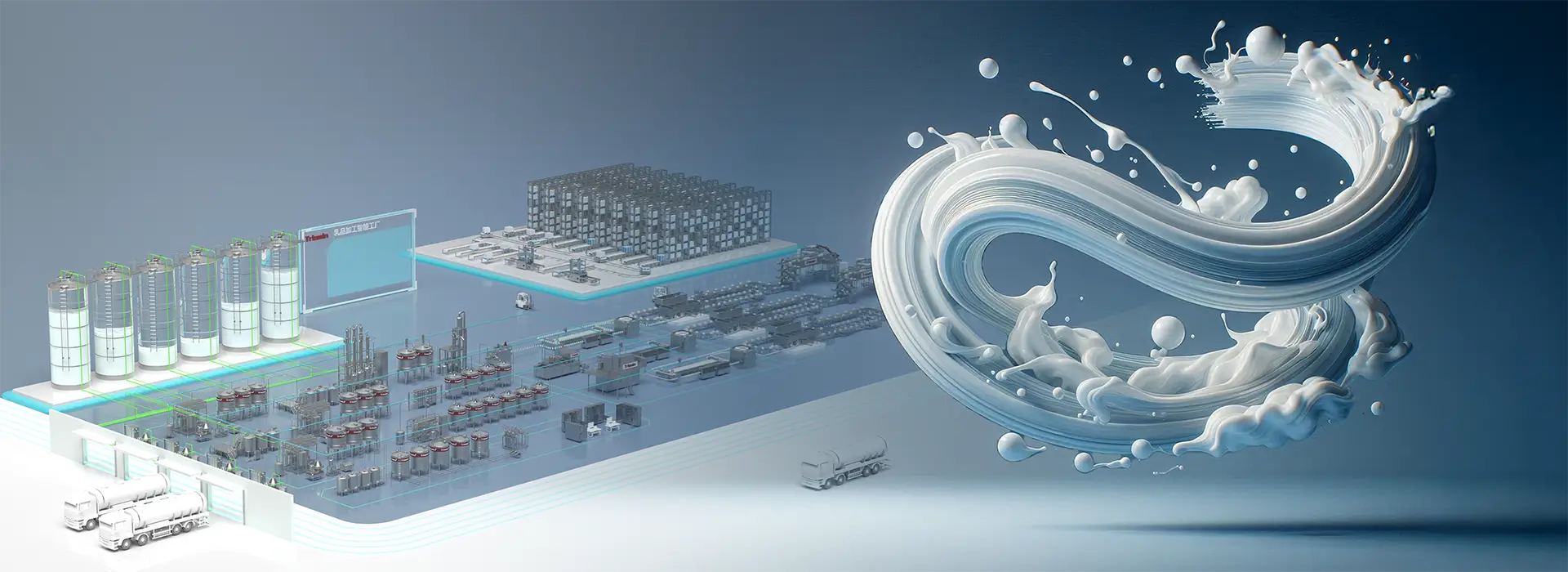

Triowin is specializing in pasteurized milk processing and equipment designed to transform raw milk from a farm into safe, packaged, and shelf-stable pasteurized milk for consumers.

The entire process is continuous, automated, and designed to be highly hygienic to prevent recontamination. Main processing as below:

1. Milk Reception

To unload he raw milk delivered by tanker, milk is pumped from the tanker into large raw milk silos for temporary storage. The milk is kept cold (around 4°C / 39°F) .

2. Standardization and Clarification

Clarification: To ensure product consistency and remove physical impurities.

Milk is passed through a clarifier (a high-speed centrifuge) to remove sediment, dirt, and somatic cells. This improves purity and taste.

Separation (Optional): If skimmed or semi-skimmed milk is being produced, the milk is passed through a separator. This centrifuge spins the milk, separating the heavier skim milk from the lighter cream.

Standardization: This is the process of blending the skim milk and cream back together in precise ratios to achieve a specific, defined fat content (e.g., Whole Milk 3.25%, 2%, 1%, Skim 0.1%).

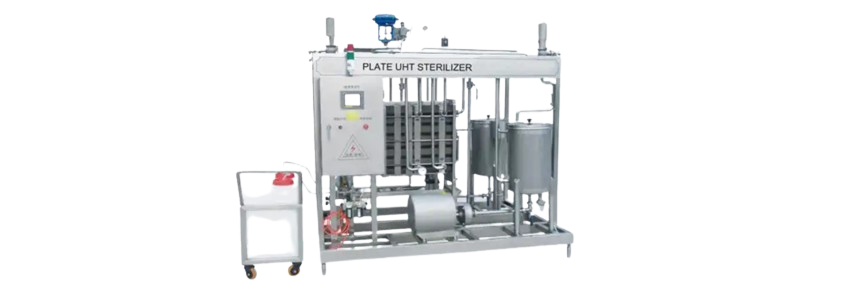

3. Pasteurization

This is the core stage of the process to destroy pathogenic bacteria and reduce the number of spoilage organisms.

This is done using a plate heat exchanger or tubular heat exchanger, which is highly efficient.

Regeneration: A key part of the heat exchanger is the regeneration section. Here, the incoming cold raw milk is warmed by the outgoing hot pasteurized milk. This saves significant energy (by pre-heating the cold milk) and simultaneously cools down the pasteurized milk.

4. Homogenization

To break down the fat globules in milk so they remain evenly distributed throughout the milk, preventing the cream from rising to the top.

This process breaks the large fat globules into tiny, uniform ones. Homogenization is usually done before sterilization to prevent any potential contamination of the pasteurized product.

5. Cooling and Storage

To rapidly cool the milk to a safe storage temperature to prevent the growth of any surviving bacteria. The cooled milk is then held in buffer tanks before filling, ensuring a continuous supply to the packaging machines.

6. Packaging

To dispense the milk into retail containers in a sterile environment without recontamination.

The cold milk is fed into automated filling machines. Common packaging types include:

Cartons: (e.g., Gable-top, Brick-shaped) made from paperboard with plastic laminate.

Bottles: Plastic (HDPE or PET) or glass.

Pouches: Low-cost plastic bags.

The filling area is a critical control point, often maintained under positive pressure with filtered air to ensure hygiene.

Download Materials

Download Materials

'

'