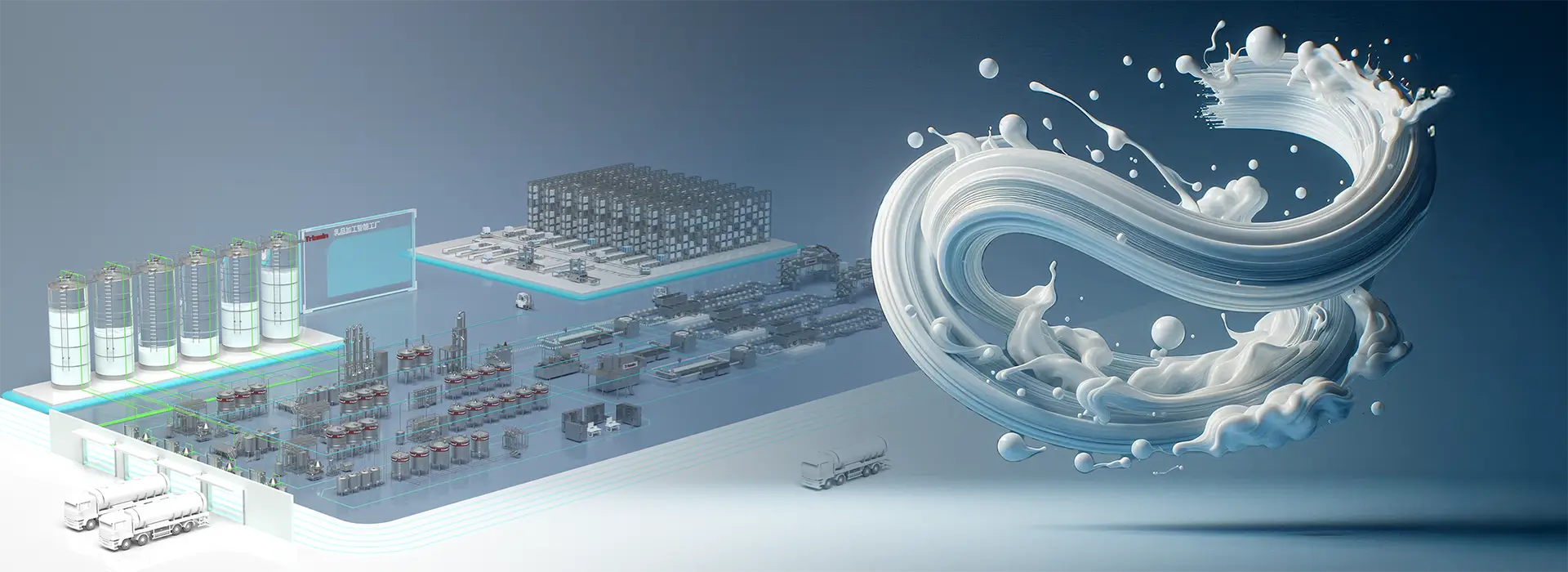

Milk Pretreatment and Standardization Line

Milk pretreatment and standardization including: Standardization, Homogenization, Pasteurization process

Standardization : Optimize Production and Reduce Waste

Standardization is a highly efficient process. It works on the principle of "separation and recombination."

Separation: Raw milk is first passed through a high-speed separator. This machine spins the milk, separating it into two streams:

Cream: A high-fat concentrate (e.g., 40% fat).

Skim Milk: A very low-fat or virtually fat-free product (e.g., 0.05% fat).

Standardization: Precise in-line sensors continuously measure the fat content of the milk stream. A computer-controlled system then automatically re-combines the exact right amount of cream back into the skim milk to achieve the desired final fat content (e.g., 3.5% for whole milk, 2% for reduced-fat, etc.).This process allows to:

Create multiple products: The excess cream not used for standardizing milk can be used to make other products like butter, whipped cream, or ice cream. This maximizes the value from the raw milk.

Minimize waste: Every part of the raw milk is utilized effectively.

Homogenization:

the purpose of milk homogenization is to create a stable, uniform, and visually appealing product that delivers a consistent taste and texture with every pour.

Pasteurization:

Triowin milk pasteurization system have been constantly developed with the highest level of product safety in a low cost and efficient way.The core nutritional components—including protein, calcium, minerals, and most vitamins—remain largely unaffected.

Download Materials

Download Materials

'

'