From mixing, homogenization and pasteurization , Freezing , Extrusion systems to clean-in-place plants, we tailor the best technologies to address your main pain points. User-friendly, enterprise-wide automation software and hardware solutions help to optimize every process line and operating parameter, without tying you in too expensive, complicated service and upgrade plans.

Solutions

- Solutions

-

Industry Solutions

- Project Cases

-

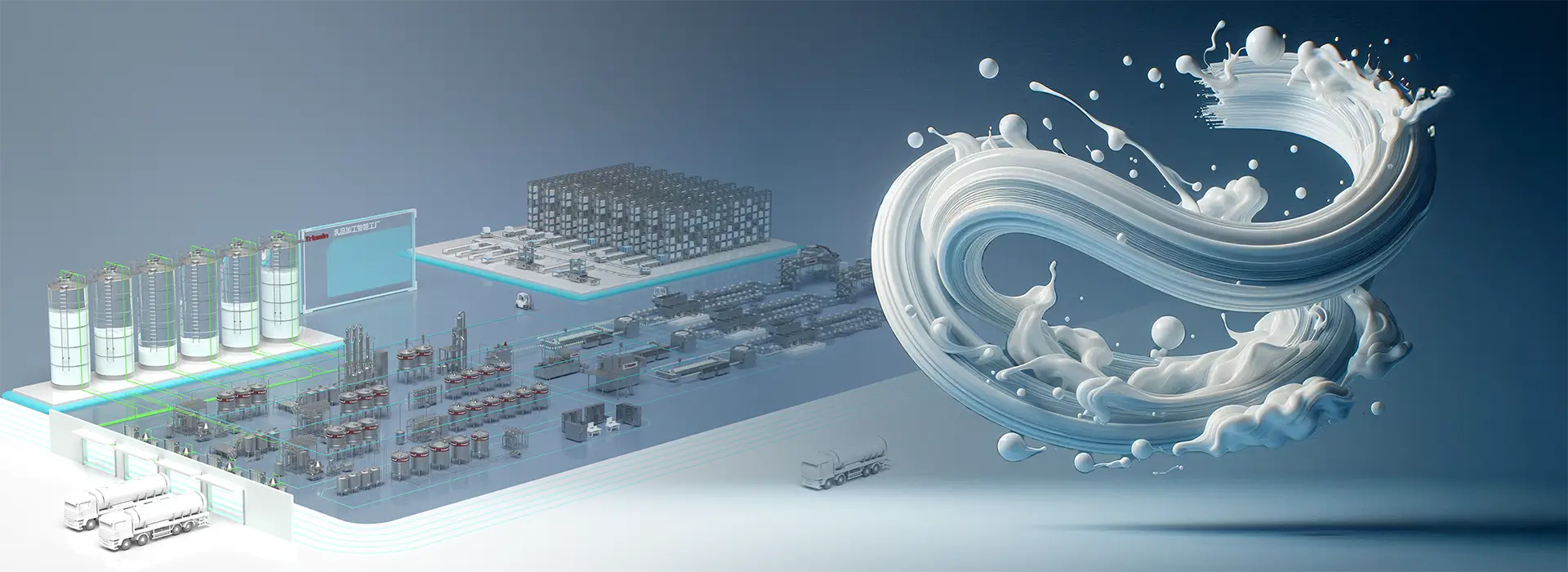

Industry SolutionsDelivering One-stop Solutions for Intelligent Production

-

Project CasesLeveraging Intelligence for Sustainable Productivity in Future Factories

Download Materials

Download Materials

'

'