-

Soybean selecting: To remove the any impurities, such as stones, dirt, or debris from the soybeans.

- Soaking and Grinding: soybean to be soaked in water, in order to extract the soy milk. Easily, the beans are ground into a slurry by milling.

-

Separation: The grinded soybean need to go through the separation to separate the soy milk from the soybean pulp. The collected soy milk is ready for further processing.

-

Cooking: The soy milk is cooked in the tank for enzyme inactivation ensure the product is safe for consumption.

-

Flavoring and Mixing: This step can add flavors, sugar, calcium or vitamins into soy milk, to enhance the taste and nutritional of the soy milk.

-

Homogenization: Homogenizer is a necessary equipment to create a smoother taste.

-

Sterilization: according to required shelf life, the soy milk can go through the UHT System for long shelf life, or go through pasteurizer processing for fresh soy milk.

-

Packaging: The final product can be filled in cartons, bottles, or pouches. This can be done according to specify requirement.

Solutions

- Solutions

-

Industry Solutions

- Project Cases

-

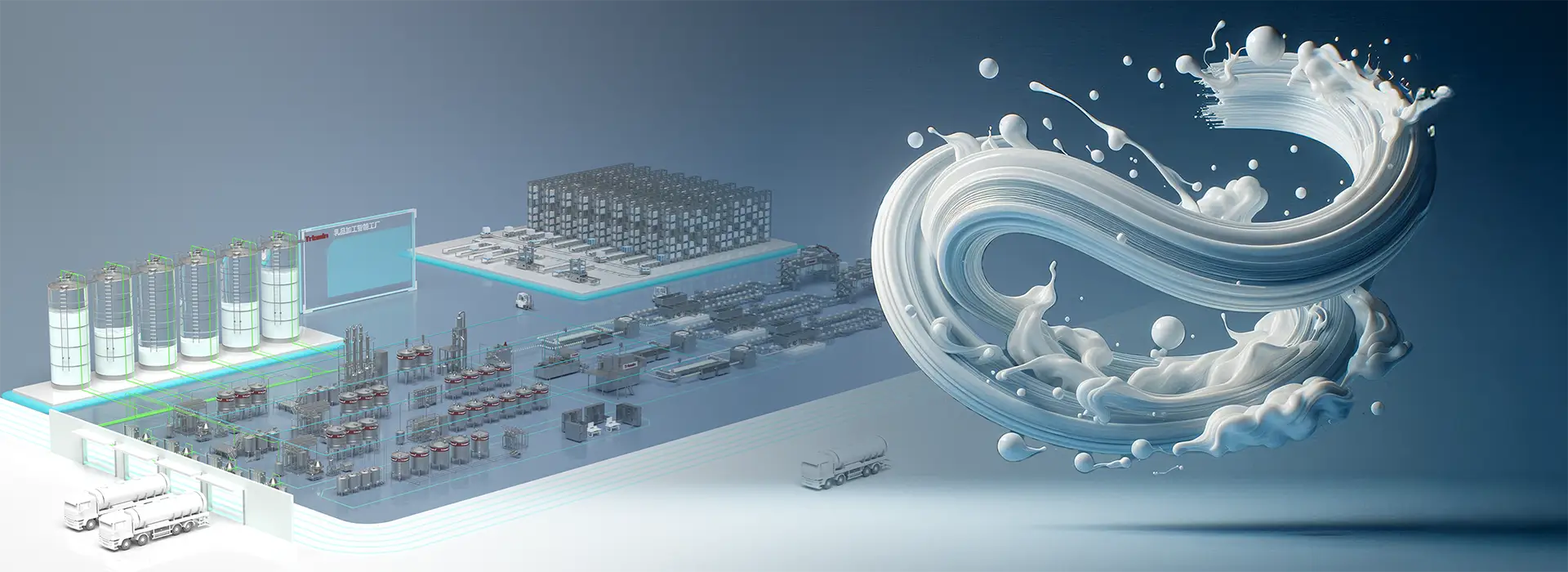

Industry SolutionsDelivering One-stop Solutions for Intelligent Production

-

Project CasesLeveraging Intelligence for Sustainable Productivity in Future Factories

Download Materials

Download Materials

'

'