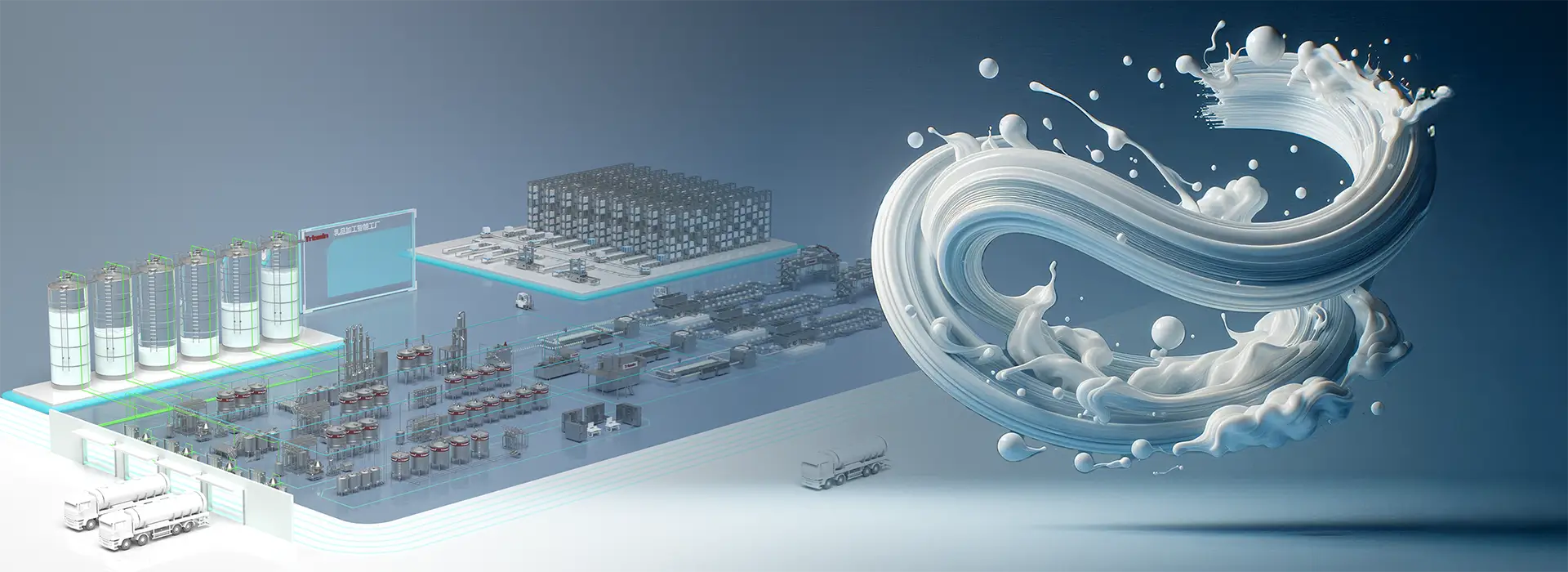

Condensed Milk and Evaperated Milk Processing Line

Triowin is specializing in the evaporated milk and sweet condensed milk processing.

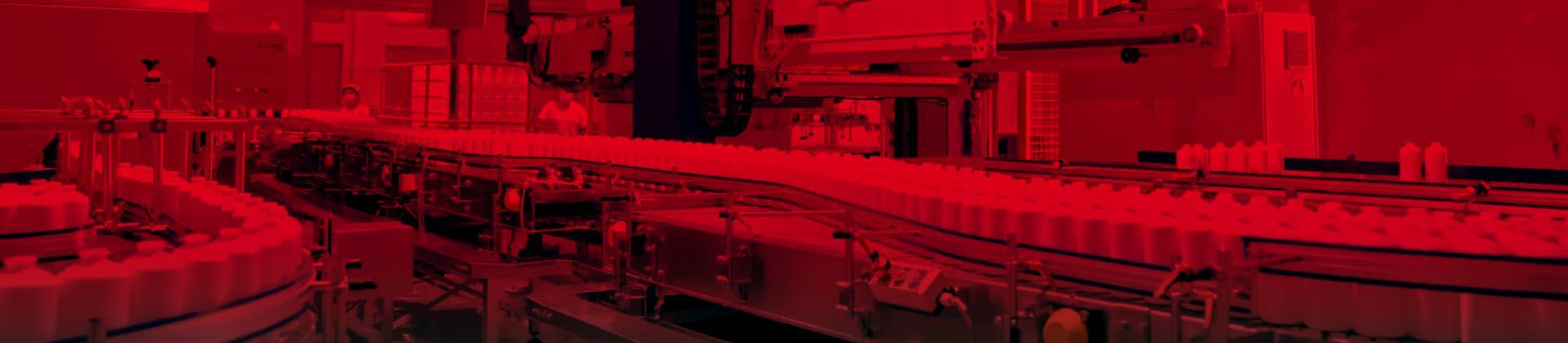

The processing line for sweetened condensed milk can be made from fresh milk or milk powder. The high sugar concentration in sweetened condensed milk increases the osmotic pressure to such a level that most of the microorganisms are inhibited or destroyed. The sugar concentration in the water phase must not be less than 62.5%.

Sweetened condensed milk must be cooled by flash cooler. This is the most critical and important stage in the whole process. It is consequently preferable to control the crystallization of lactose so that very small crystals are obtained. The required crystallization is accomplished by cooling the mixture rapidly under agitation without air being entrapped. The cooled condensed milk is pumped to a storage tank where it is kept until the crystallization process to be completed.

Traditionally, SCM and evaperated milk filled in cans. Nowadays it is also possible to pack evaperated milk in aseptic paperboard packages. The product is also packed in big barrels, holding about 300kg for supply to large-scale users.

Download Materials

Download Materials

'

'