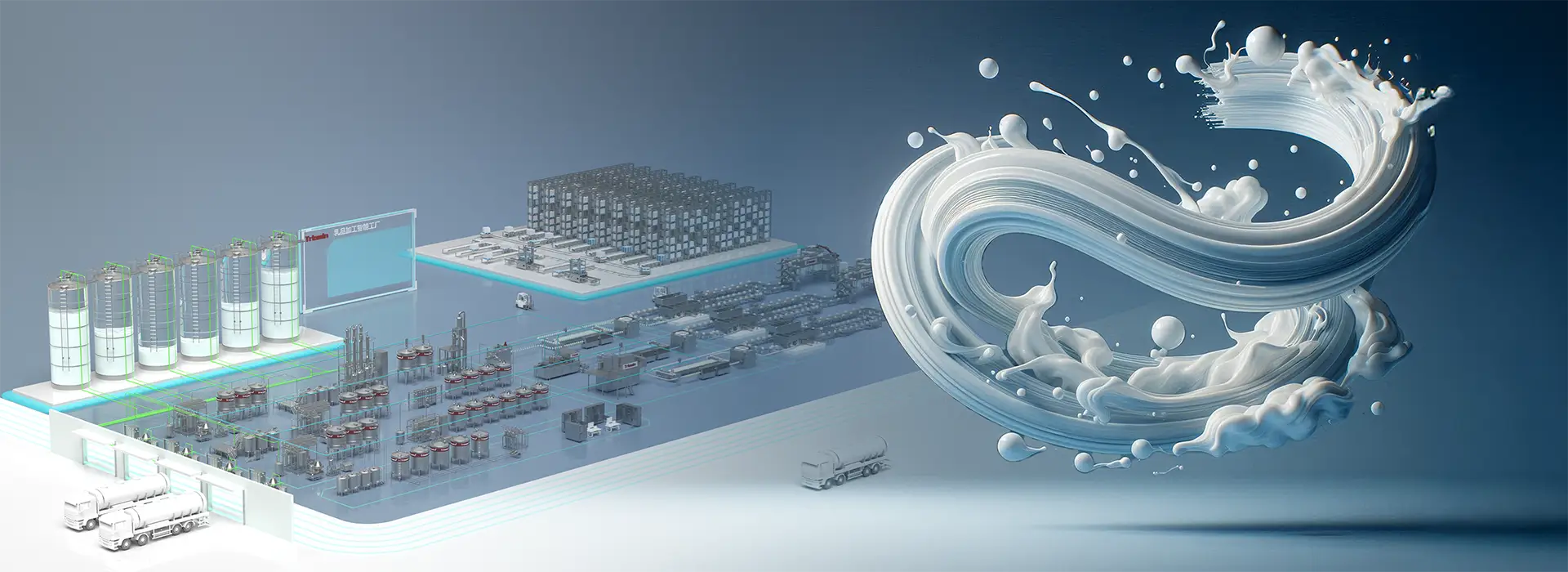

Yogurt Processing Line

When manufacturing diverse products that may include set, stirred or strained yogurts, drinking yogurts, sour milk drinks,

Because you need to derive maximum value from expensive capital investments, our specialists work to configure and install hardworking, easily maintained and robust process lines that can adapt as you grow, expand, and diversify. Where possible options include skid-mounted, plug-and-play equipment that can minimize on-site assembly costs and commissioning time, and give you the flexibility to adapt and adjust your processes as required.

Working with a single supplier for your complete process lines means you can expect seamless integration of equipment at every stage, including upstream solutions for milk reception, separation, standardization, mixing, pasteurization, fermentation, filling and packing.

Pre-treated milk is cooled to the incubation temperature and then continuously pumped into the fermentation tank along with the required volume of starter culture. The fermentation tank is insulated to maintain a constant temperature throughout the incubation period. To monitor the development of acidity within the tank, a pH meter can be installed. The incubation time for typical stirred yogurt production ranges from 2.5 to 3 hours at 42-43°C, utilizing a common production culture (inoculation amount: 2.5-3%). To achieve optimal product quality, bacterial fermentation must be terminated when the pH reaches the desired value and the product temperature should be rapidly cooled from 42-43°C to 15-22°C, Simultaneously to ensure the desired viscosity of the finished product, gentle mechanical treatment of the curd is crucial.

Fruit and flavoring ingredients can be dosed into yogurt during the transfer of yogurt from the buffer tank to the packaging machine. This is accomplished by a variable-speed metering pump that continuously injects these ingredients into the yogurt stream. The inline mixer is ensuring complete and consistent integration of the fruit and yogurt. The fruit metering pump and the yogurt feed pump operate synchronously.

Download Materials

Download Materials

'

'