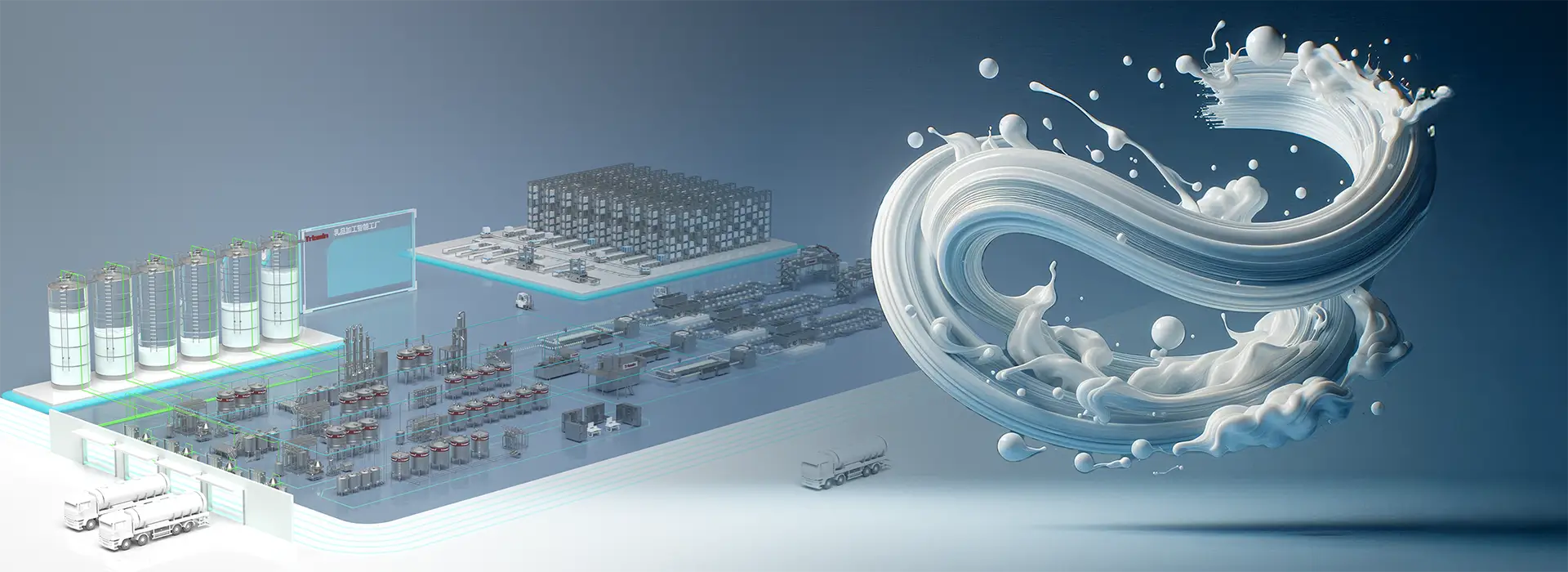

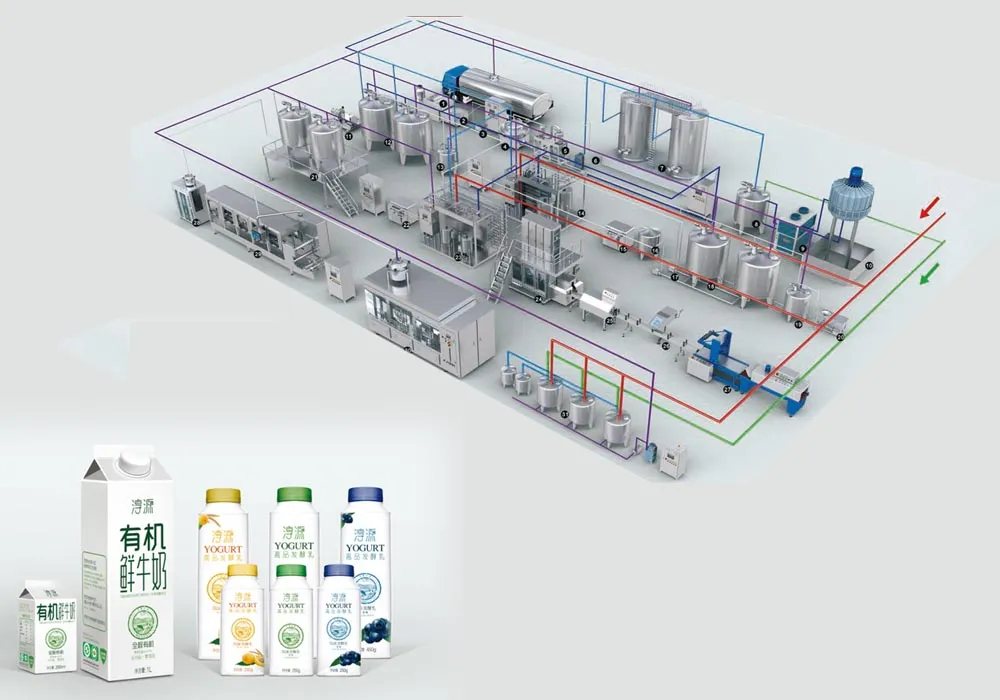

We can offer components, equipment, and process lines for all types of UHT milk, We continuously innovate to develop new solutions that could help you save energy, recycle waste heat and water, and improve your environmental footprint. However, complex your batch or continuous process, and whatever your production scale, our equipment is designed to help you precisely control and optimize just about every stage, from milk and ingredients reception, milk separation, treatment and standardization, through to aseptic storage, filling and packaging.

The UHT milk processing line can produce plain milk, skim milk products, yoghurt drinking, soy bean milk etc.

First the milk is preheated and standardized by in line milk standardization system. Then the standardized milk is homogenized. Then milk is pumped to the heating section of the milk heat exchanger where it is sterilized. The necessary holding time is provided by a separate holding tube. The UHT temperature is recorded continuously. Pump is a booster pump which increases the pressure of the product to a level at which the sterilized product cannot be contaminated by untreated milk or by the cooling medium if a leak occurs in the heat exchanger. After sterilization the milk continues to a cooling section in the heat exchanger, where milk is cooled by the incoming untreated cold milk in heat regeneration section, and then to the cooling section where it is cooled with ice water. The cold milk is then go to the aseptic tank & filling machines.

Download Materials

Download Materials

'

'